T&G Engineering are at the C.O.R.E. of innovation and precision grinding

T&G ENGINEERING CO. LTD, based in West Byfleet are a leading sub-contract manufacturing company who are well-known for their ability to produce the most challenging and complex components to the tightest tolerances and highest standards.

The ability to do this consistently comes not only from the highly skilled workforce and the company-wide ethos of continual improvement but also from the desire to constantly invest in the very best machines and cutting-edge technology. To Be the first and to be the best.

The ability to do this consistently comes not only from the highly skilled workforce and the company-wide ethos of continual improvement but also from the desire to constantly invest in the very best machines and cutting-edge technology. To Be the first and to be the best.

When it comes to Cylindrical Grinding, it is no surprise that T&G achieve this using STUDER Universal CNC Grinding Machines. When they ordered their very first Studer S31 more than 20 years ago, that machine was configured with features like High-speed form (un-round) grinding, to ensure that they can grind anything that their customers might need now and in the future. Today, their Studer range of machines have grown to also include the S21 and S40, also equipped to the highest specifications.

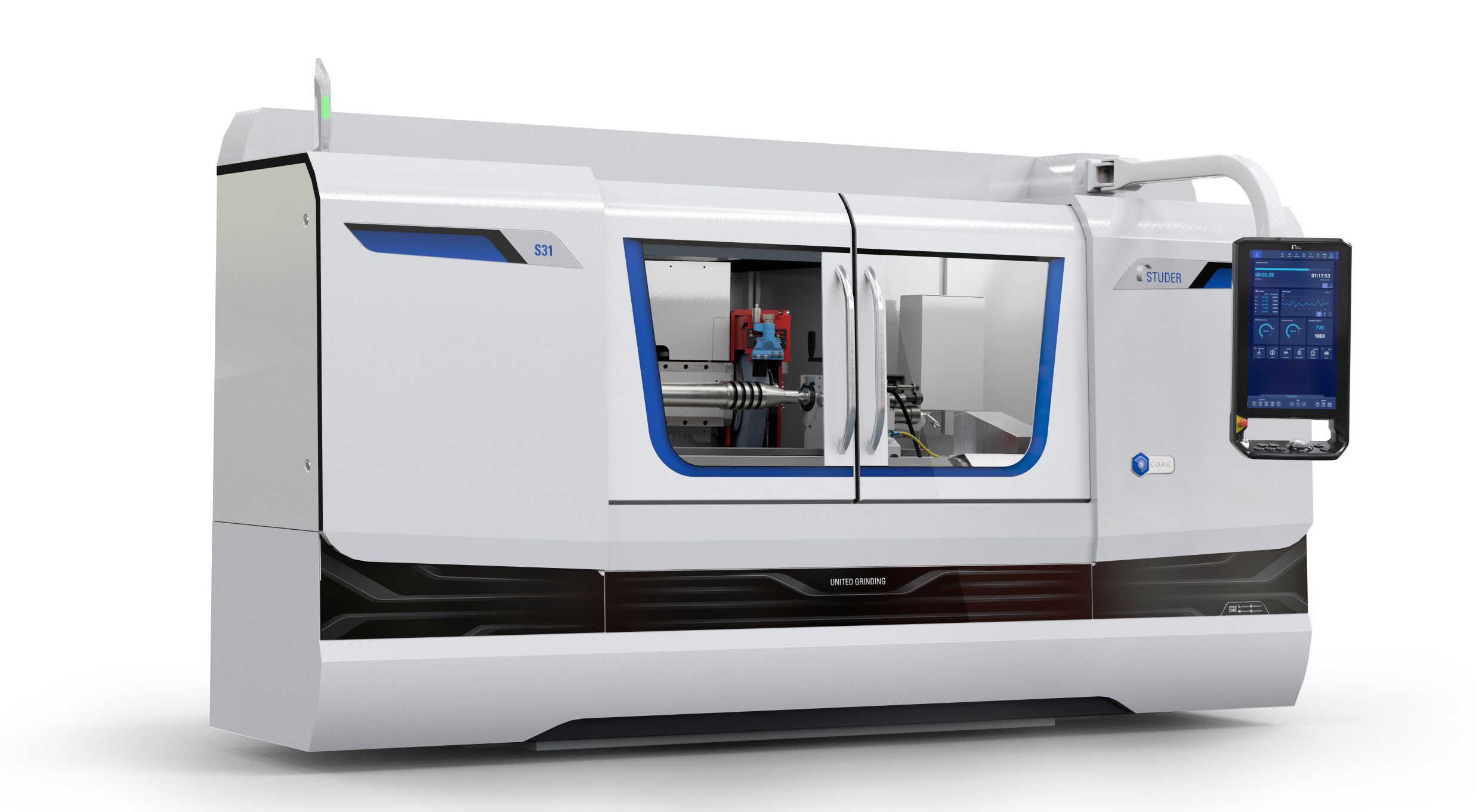

To ensure that they stay one step ahead of the competition, when Studer and the United Grinding Group unveiled their new C.O.R.E. control and operating system, T&G Engineering wanted to be at the front of the line by being the first company in the UK to take delivery of the latest design of the Studer S31 with the latest C.O.R.E. controland operating system on a machine configured with the very latest technology.

To ensure that they stay one step ahead of the competition, when Studer and the United Grinding Group unveiled their new C.O.R.E. control and operating system, T&G Engineering wanted to be at the front of the line by being the first company in the UK to take delivery of the latest design of the Studer S31 with the latest C.O.R.E. controland operating system on a machine configured with the very latest technology.

ADVANCED GRINDING SUPPLIES LTD, who are the exclusive agents for Fritz Studer for the South UK & South Wales, have worked closely with T&G Engineering for many years as alongside of the machines, AdGrind are exclusive agents, distributors, and stockists for some of the leading names in abrasives and machinery including MEISTER ABRASIVES, ALFONS SCHMEIER ABRASIVES, SAINT-GOBAIN Abrasives (Norton, Flexovit, Baystate etc.), TECHNICA TECHNOLOGIES (Centre Grinding Machines), as well as having their own range of Natural Diamond and Synthetic Dressing Tools, a full range of Coolant Filter Media (filter paper) rolls, Precision Live & Dead Centres, Face Drivers and more.

When the new C.O.R.E. control was unveiled, Tony Smyth, Managing Director of T&G Engineering and Peter Harding from Advanced Grinding Supplies started discussing the ideal Studer machine that would meet T&G Engineering’s highest demands. As a result, T&G Engineering will soon be taking delivery of the very first Studer machine in the UK with the latest C.O.R.E. Operating System.

This new Studer S31, with the capacity for parts up to 1000mm between centres, with its 2 x External Grinding Wheels, 1 x Internal Griding Spindle will be equipped for External and Internal Cylindrical Grinding, High-Speed Form Grinding, Thread Grinding, HF Dressing Spindle for dressing the latest in Super Abrasives (CBN & Diamond).

With this continuous investment in the very latest machine tools and technology, T&G Engineering ensure that they remain preferred and established partners for their customers in Aerospace, Automotive, Motorsport, Pharmaceutical, Medical, Can Tooling and Special Purpose Machinery industries. Advanced Grinding Supplies are proud to work with T&G Engineering and look forward to them putting the new Studer S31 through it’s paces.

Contact Advanced Grinding Supplies for any informaiton on the Studer range of machines, Abrasives, Dressing Tools, Filter Media, Tooling & Consumables