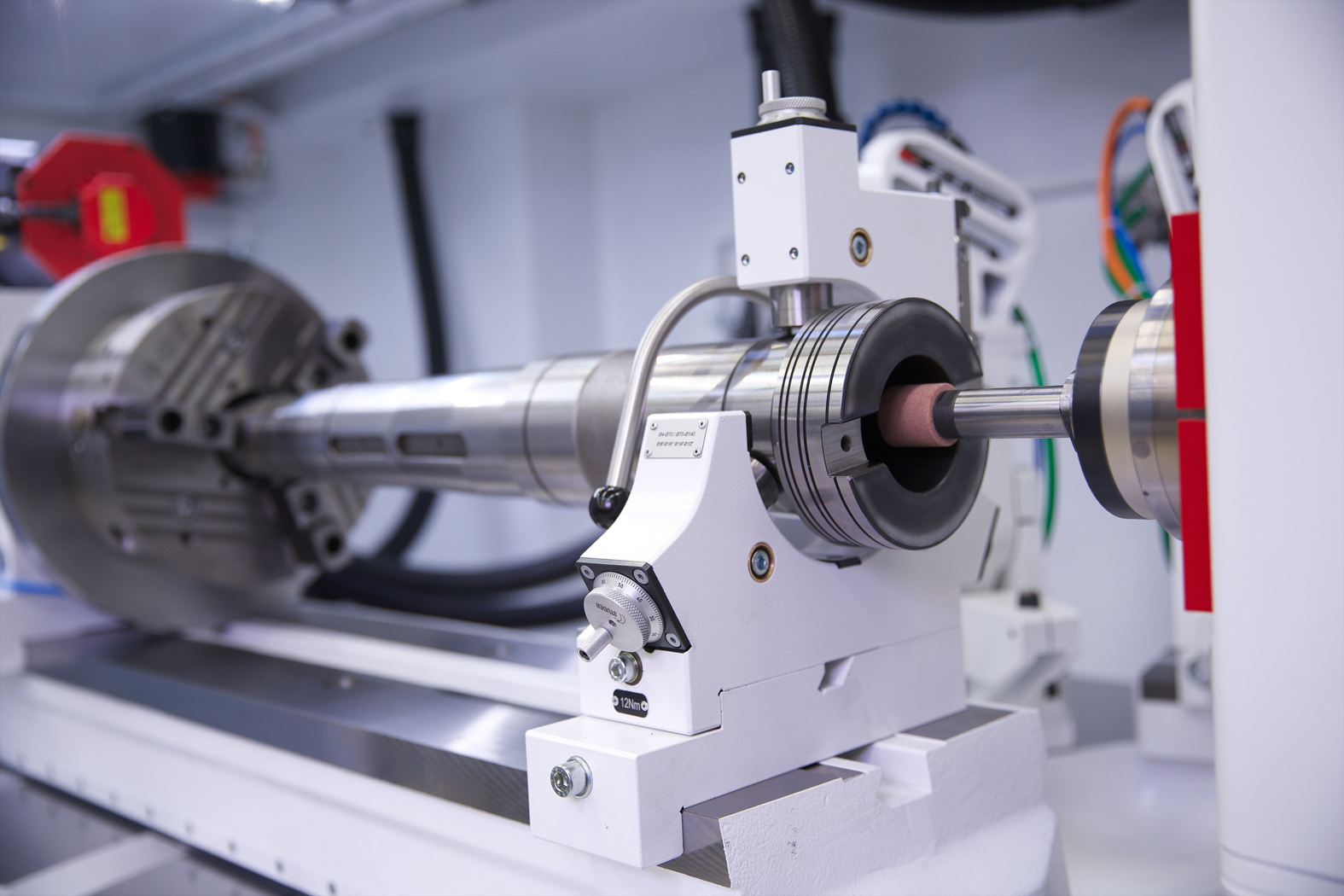

The internal cylindrical grinding machine for short and long workpieces

The internal cylindrical grinding machine for short and long workpieces

The NEW STUDER S141 CNC Universal internal cylindrical grinding machine has been designed from the ground up using the decades of grinding experience and machine building expertese from Studer. With this world innovation, the Studer S141 universal internal cylindrical grinding machine, STUDER is advancing into a new market segment, namely that of internal grinding of long work-pieces.

The Studer S141 is the ideal machine for grinding spindle shafts, spindle housings, rotor shafts or axels. Many workpieces are in the areas of machine tools, drive elements, aerospace and tool making.Short workpieces clamped in a chuck, but primarily long workpieces up to 1300 mm with an additional steady-rest are the speciality of the new Studer S141.

The maximum internal grinding length is 250 mm while the external length is 150 mm. The swing diameter above the table is 400 mm, the maximum workpiece weight is 250 kg. These are truly impressive statistics for the latest development from world leaders in Cylindrical Grinding Machines.

Characteristics:

- All axes are equipped with linear drives

- The patented StuderGuide® guide way system ensures fast, high-precision axis movements

- Automatic swiveling of the workpiece table for axis-parallel grinding of cones / tapers

- The perfect dressing strategy for every application, with up to two dressing stations

- Acoustic touch sensor technology for dressing and grinding processes

- Grinding software developed by grinding specialists for demanding users

- Granitan® machine bed with outstanding damping characteristics

- Grinding spindle turret with direct drive, up to four grinding spindles, including a maximum of two external grinding spindles

- Grinding quill length up to 265mm

- Integrated axial/radial measuring probe for length positioning and process support

- Consistent implementation of BlueCompetence

- Extensive range of accessories

With the S141 STUDER brings another “Trend Setting” internal cylindrical grinding machine to the market, which thoroughly impresses with its technical features and the proverbial STUDER precision.